Error Encased

The manufacturing of encased is a process where a coin, usually a cent, is placed on an anvil die. Then the hammer die comes down and strikes the aluminum ring encasing the coin. At the same time, raising the legend on the ring. The coin has to be oriented so that the head on the obverse is upright when struck. I believe that this process is done by hand for each strike. If the coin was feed into the die with the ring using automation could the orientation be assured?

Images are courtesy of Hal Greimann.

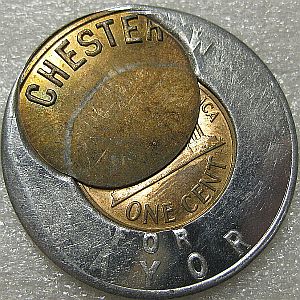

Obverse error encased cent. Round encasement, cent partially flattened, incomplete legend.

Reverse or error encased cent. A econd coin was in the press at the same time.

It would appear that a second coin was inserted in the press as well as one on the anvil die. Anvil dies have an inset center that holds the cent as it is struck. The strike squeezes the encasement and coin together fixing the coin in place. In this case, a second coin was in the die. The result has the second coin pressed into the reverse of the coin and the encasement. Due to the extra thickness of the additional coin, only some of the legend was pressed into the aluminum ring. So how did this occur? If the coins are inserted by hand, then the hammer die is engaged to make the piece, this would have to be deliberate. Having no clear knowledge of the exact process I can only speculate. If you have information on how encased are manufactured, please submit an article!

Edge view of the error encased.

In the image above you can see where the edge is made thicker by the additional coin. Usually when a coin isn't in the correct orientation it is indicative of a replaced coin. Here the only possible way to manufacturer this error is the additional coin being place in the press.

Home | Articles | Varieties | Coin Links | About | Terms of Use

Site Copyright 1999-2021 by Bruce Perdue Email: Webmaster All Rights Reserved ©Copyright Bruce Perdue